IceLoss2.2 – the updated next generation icing loss assessment model for wind farms

The updated IceLoss2.2 has now been launched commercially, and the results look even better than for the previous IceLoss2.1 model that had the lowest overall validation uncertainty in the industry. IceLoss2.2 is a state-of-the-art model used to predict icing losses for planned wind farms. In the Nordics, icing losses are typically the 2nd largest source of production loss after wake losses for wind farms.

The updated IceLoss2.2 is based on newest internal research efforts during 2022-2023 using latest turbine data and model improvements. The original IceLoss2.0 research project was funded partly by the Swedish Energy Agency during 2019-2021.

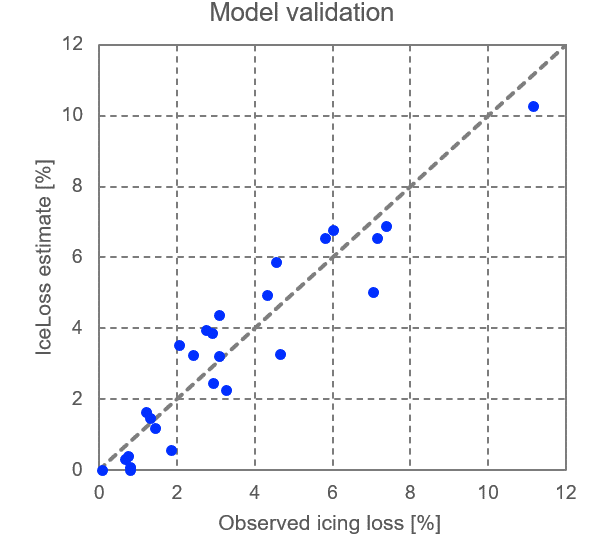

The updated IceLoss2.2 model has been extensively validated with 26 wind farms consisting of around 2100 turbine years of production data. The validation results show an improved average mean absolute error and decreased uncertainty compared to the previous IceLoss2.1 model.

Figure 1. IceLoss2.2 model validation results

What were the main reasons to update the IceLoss model?

The updated IceLoss2.2 model performance has been improved using more operational wind farms (22 -> 26) using data from more relevant, larger wind turbines and other model improvements. The new IceLoss2.2 model shows a smaller mean absolute error and increased r^2 correlation compared to previous model version.

“Even though we have performed over 200 IceLoss projects in the Nordics to-date since 2010, the fast turbine technology trend towards bigger and higher turbines require constant model updates to decrease model uncertainties. We saw it as important to utilize the latest operational experiences from the new wind farms being built in the Nordics.” says Simo Rissanen, Senior Adviser at Kjeller Vindteknikk.

What are the key benefits of the new model?

“Most importantly, we are using the latest, large turbine data to calibrate the model in order to predict more accurately the icing losses for new wind farms under development.” says Øyvind Byrkjedal, Team Leader at Kjeller Vindteknikk. “We also have an updated and improved ice protection system module for analysing turbines with heated blades.”

More information about the IceLoss product available here: https://www.vindteknikk.com/services/wind-energy/iceloss/

You are welcome to contact us for more info!